They work by pinching the flat sheet between two vertically opposed rolls while the third offset roll or bending roll moves upward to contact and then bend the sheet.

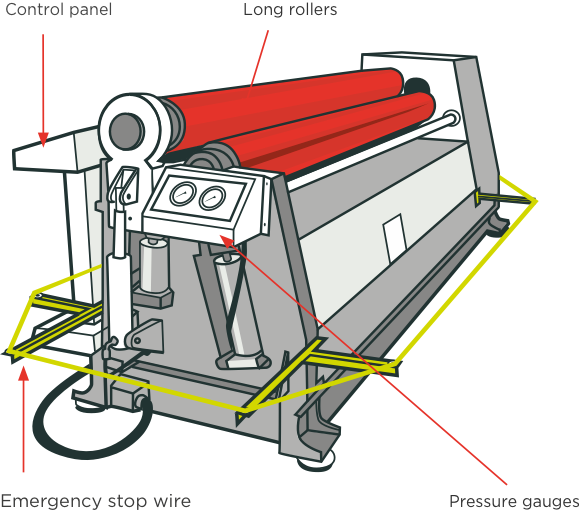

Steel plate bending machine hazards.

Power roll forming and bending machine conventional metal forming and bending machines also known as plate bending rolls produce smooth circular bends in sheet strip or coiled stock.

Safety precautions while using a sheet metal bending machine to get the desired output and for safe operation you are required to follow some basic safety norms while using a sheet bending machine.

What s more it will reduce the cost of repairs.

Three roll initial pinch see figure 5 or single initial pinch plate rolls generally are for light capacity applications and may be electromechanical or hydraulic.

Kick plate trip device hold to run control forward and.

The operator should know clearly of rollingmachine structure performance controller operation and different work piece rolling process.

A closer look at machine styles.

Metal is fed between successive pairs of rolls.

With the improvement of vehicle lightweight and collision safety the application of high strength steel plate in the automobile industry is increasing gradually.

At present high strength plate bending parts are mainly applied to structural parts in automobile chassis.

This post will explain some safety tips that you need to take into account while using a sheet metal bending machine.

Safe use of 3 roll bending machines introduction.

Guidance may be applied to other types of bending machines where similar hazards and risks are present.

That progressively bend and form it until the desired shape and cross section is obtained.

2020 year safety stainless steel plate sheet metal bending machine press brake find complete details about 2020 year safety stainless steel plate sheet metal bending machine press brake machine bending sheet metal machine bending stainless steel plate sheet metal machine bending from press brake supplier or manufacturer anhui runbang heavy industry machinery co ltd.

Hazards and risks the main hazard at these machines is the operator s hands being caught and drawn into the in running nip.

Amazing biggest steel bending machine at work fast extreme large plate rolling machines.

Sheet metal bending can be done in two ways.

When the operation of a machine or accidental contact injure the operator or others in the vicinity the hazards must be eliminated or controlled.

3 roll plate bending machine correct use and proper maintenance can extend the using life.

This page contains general information on the various hazards of mechanical motion and techniques for protecting workers.

While this guidance has not been updated to reflect current work health and safety legislation the health and safety at work act 2015 and regulations it may still contain relevant information and practices to keep workers and others healthy and safe.